Reasons Why You Should Use CNC Machining Services

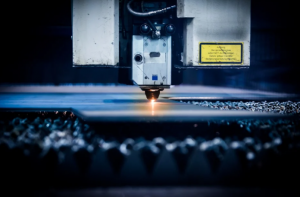

If you want to own your products manufactured, there are various alternatives you can choose. You can have it cut by laser, hand-made, die-cut, or machined. It is CNC machining that offers the best alternative for anyone looking for exact, high-quality parts. In this guide, we examine the reasons why you need to use CNC machines.

It Offers Highly Accurate Results

Many CNC production methods work in two ways. Today’s most popular form of production is to use a CNC punch profiler or even a CNC laser cutter. These two can cut flat sheet metal parts. This way, you can produce precise components, but you have no control over that sheet’s depth. The thickness of the sheet can vary across the entire sheet. This can make it difficult to cut the same area, even if you cut on the same sheet. In this way, the dimensions of this product can be produced to precise specifications.

It Reduces the Costs

CNC machining can be quite expensive. A less expensive option is the combination of the laser-cut method with CNC machining. The part can be cut a few millimeters more than necessary, while the machine tool is guided along the outside of the profile to ensure that it is within the important dimensions. A workpiece cut from a 12mm steel sheet, which is then reduced to 10mm by a machining center, is easy and makes a precise workpiece more economical than all-machine cutting.

CNC machining can be quite expensive. A less expensive option is the combination of the laser-cut method with CNC machining. The part can be cut a few millimeters more than necessary, while the machine tool is guided along the outside of the profile to ensure that it is within the important dimensions. A workpiece cut from a 12mm steel sheet, which is then reduced to 10mm by a machining center, is easy and makes a precise workpiece more economical than all-machine cutting.

It Results in High-Quality Products

There will be no distortion due to excessive heat when cutting the fabric. This manufacturing technique also leaves a completely clean edge without burrs or damage to the fabric. Anyone interested in purchasing high quality and precision components should consider processing because they have chosen the production of their choice. This is ideal for interlocking gears and racks or high precision elements for the healthcare industry.

Finding the Best CNC Machining Service Is Simple

To find the best and most reliable CNC machining solutions, you need to think about finding a company that offers these basic skills. You need to know what you want, as it comes in two different forms. It also provides versatile workpiece and filler part movements. Its performance is based exclusively on its integrated software management system. Many CNC milling machines are programmed to perform complex milling operations with a minimum of contact.